Johnny's Dart repairs

Moderator: Moderators

all the dana/spicer/borgwarner axles are the same

all shims and no threaded adjusters

dana 44 has been around since 1940s you just have a modern version. its going to be well supported and not just by the aftermarket

RATECH

will have all the bits you want for installing your centre

but then again your local jeep garage probably does as well

http://www.ratechmfg.com/dana.htm

dana instructions they are all the same

http://www2.dana.com/pdf/AXSM-0053.pdf

Dave

all shims and no threaded adjusters

dana 44 has been around since 1940s you just have a modern version. its going to be well supported and not just by the aftermarket

RATECH

will have all the bits you want for installing your centre

but then again your local jeep garage probably does as well

http://www.ratechmfg.com/dana.htm

dana instructions they are all the same

http://www2.dana.com/pdf/AXSM-0053.pdf

Dave

The Greater Knapweed near the Mugwort by the Buckthorn tree is dying

- Johnny Dart

- Posts: 850

- Joined: Tue Dec 24, 13 12:46 pm

- Location: East Sussex

It looks like I'll be starting the rear axle next week now.

Everything just seams to get in the way !

I only had one kick panel when I got the Dart, so was about to import another one , when I came across these kick panels with speakers built in,

so I imported these instead.

I fitted them today, together with a pair of parcel shelf speakers.

Everything just seams to get in the way !

I only had one kick panel when I got the Dart, so was about to import another one , when I came across these kick panels with speakers built in,

so I imported these instead.

I fitted them today, together with a pair of parcel shelf speakers.

- autofetish

- Posts: 5599

- Joined: Sat May 21, 11 6:43 am

- Johnny Dart

- Posts: 850

- Joined: Tue Dec 24, 13 12:46 pm

- Location: East Sussex

I mounted up the electric fan this evening, it's a 16" 120w item.

Wired up through a fan switch,that I fitted to the bottom tank of the rad , in place of the drain bung.

I cut out the drain bung , and soldered in a brass thin nut , to take a generic 22mm fan switch.

This is wired through a relay, to operate fully auto.

Have to see how well it works

Lower rad crossmember has taken a bit of a poggering, and will need to be straightened out, while the rad is out

Wired up through a fan switch,that I fitted to the bottom tank of the rad , in place of the drain bung.

I cut out the drain bung , and soldered in a brass thin nut , to take a generic 22mm fan switch.

This is wired through a relay, to operate fully auto.

Have to see how well it works

Lower rad crossmember has taken a bit of a poggering, and will need to be straightened out, while the rad is out

- Johnny Dart

- Posts: 850

- Joined: Tue Dec 24, 13 12:46 pm

- Location: East Sussex

- autofetish

- Posts: 5599

- Joined: Sat May 21, 11 6:43 am

- Johnny Dart

- Posts: 850

- Joined: Tue Dec 24, 13 12:46 pm

- Location: East Sussex

- Johnny Dart

- Posts: 850

- Joined: Tue Dec 24, 13 12:46 pm

- Location: East Sussex

- autofetish

- Posts: 5599

- Joined: Sat May 21, 11 6:43 am

- Johnny Dart

- Posts: 850

- Joined: Tue Dec 24, 13 12:46 pm

- Location: East Sussex

- Johnny Dart

- Posts: 850

- Joined: Tue Dec 24, 13 12:46 pm

- Location: East Sussex

- Johnny Dart

- Posts: 850

- Joined: Tue Dec 24, 13 12:46 pm

- Location: East Sussex

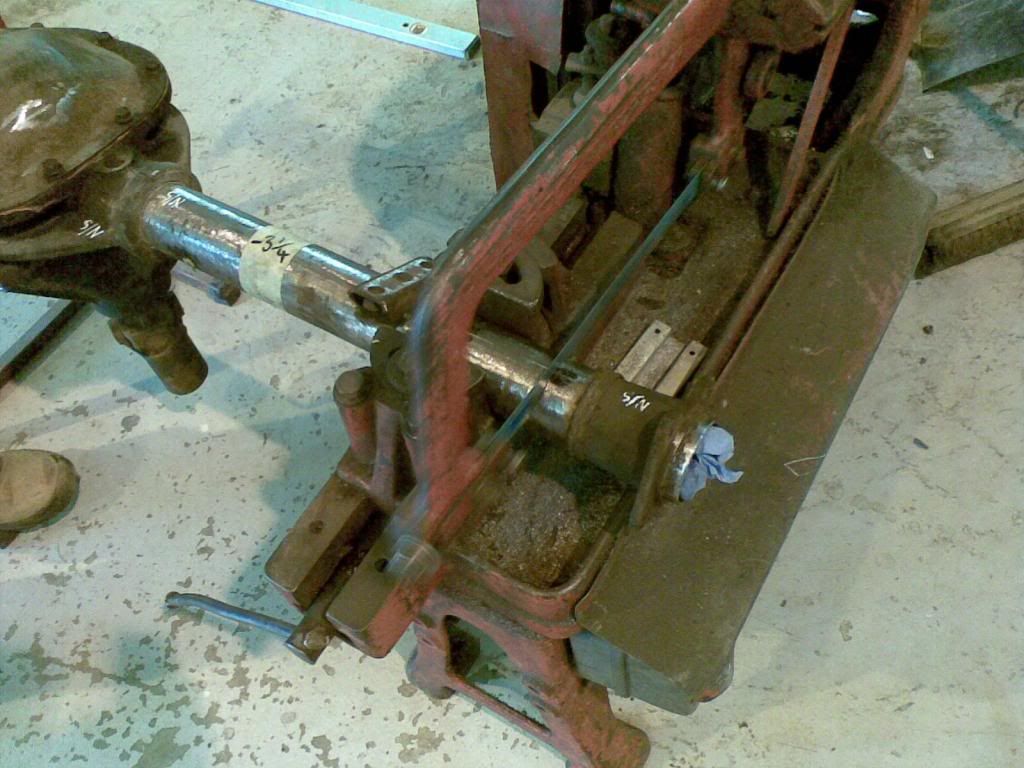

A bit more lunch hour work today.

Welded the axle ends, and now finished the axle, apart from offering it up with the wheels on , and centralising it with the wheel tubs, and leaf springs, tack the spring perches, with the right pinion angle ect.

I now need to start on the half shafts.

Welds placed to minimise distortion.

Welding round the ends.

Done

Welded the axle ends, and now finished the axle, apart from offering it up with the wheels on , and centralising it with the wheel tubs, and leaf springs, tack the spring perches, with the right pinion angle ect.

I now need to start on the half shafts.

Welds placed to minimise distortion.

Welding round the ends.

Done

- Johnny Dart

- Posts: 850

- Joined: Tue Dec 24, 13 12:46 pm

- Location: East Sussex

Thanks Steve, yes I do have access to tools ect, and it does make a job easier.Steve wrote:Very nice work mate...and looks like you have all the kit as well....fantastic!

Still quite a bit to do. The shortening of the axle case was quite easy, and I could do it all myself.

Shortening the axles themselves is another story.

I can't do that, but have a friendly guy with a machine shop that has a cunning plan to shorten the shafts.

I then need to fit the diff centre locker.

Watch this space